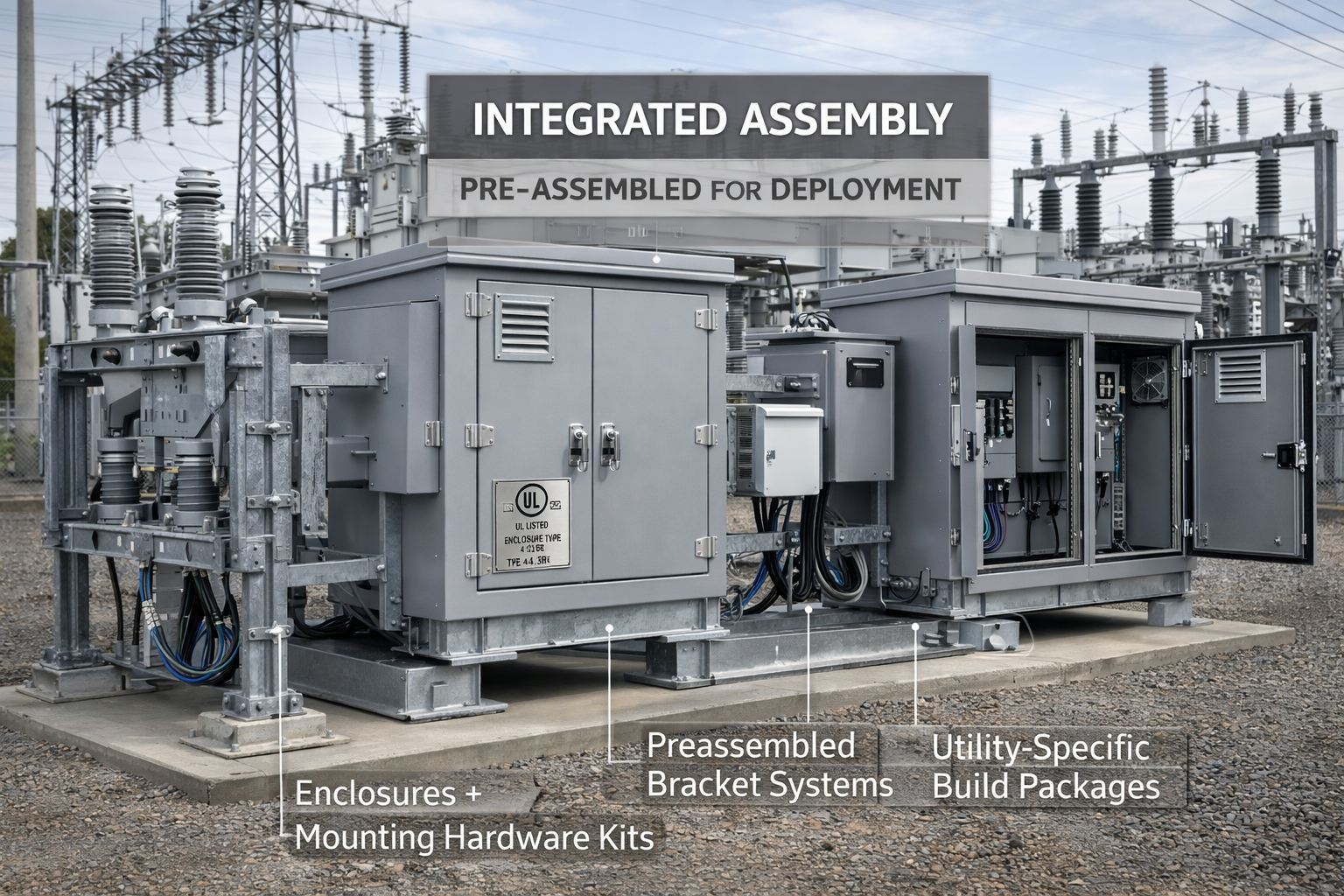

Integrated Assemblies

Pre-Engineered Systems Ready for Deployment

-

Our integrated assemblies move beyond component supply to deliver complete, specification-ready systems. Each package arrives with all mounting hardware, structural supports, and installation components factory-assembled or systematically kitted for immediate deployment.

Purpose-built for utility and substation projects where installation timelines, labor costs, and field coordination drive project efficiency. We eliminate the procurement fragmentation of sourcing enclosures, brackets, hardware, and accessories from multiple vendors.

-

Integrated assemblies leverage full in-house fabrication and assembly processes:

Laser cutting and CNC forming for precision component manufacture

Robotic welding for structural connections and bracket assemblies

Controlled assembly environment for multi-component integration

Protective finishing (powder coating, galvanizing) applied to complete assemblies

Systematic kitting and packaging with installation documentation

-

All integrated assemblies manufactured under documented quality processes:

UL Listed enclosures and compliant component integration

NEMA environmental ratings maintained through assembly process

Fastener torque specifications and installation procedures documented

Pre-delivery inspection of assembled systems and hardware kits

Full material traceability and QA/QC documentation packages

-

Integrated assemblies serve installations requiring coordinated deployment:

Substation control and relay panel installations

Distributed power monitoring and communications nodes

Pad-mounted equipment with standardized enclosure/bracket systems

Multi-site deployments with consistent configuration requirements

Fully integrated enclosure assemblies designed, fabricated, and kitted for direct installation. From complete enclosure and mounting hardware packages to pre-assembled bracket systems—engineered solutions that reduce field labor and eliminate on-site assembly variables.